Case Studies

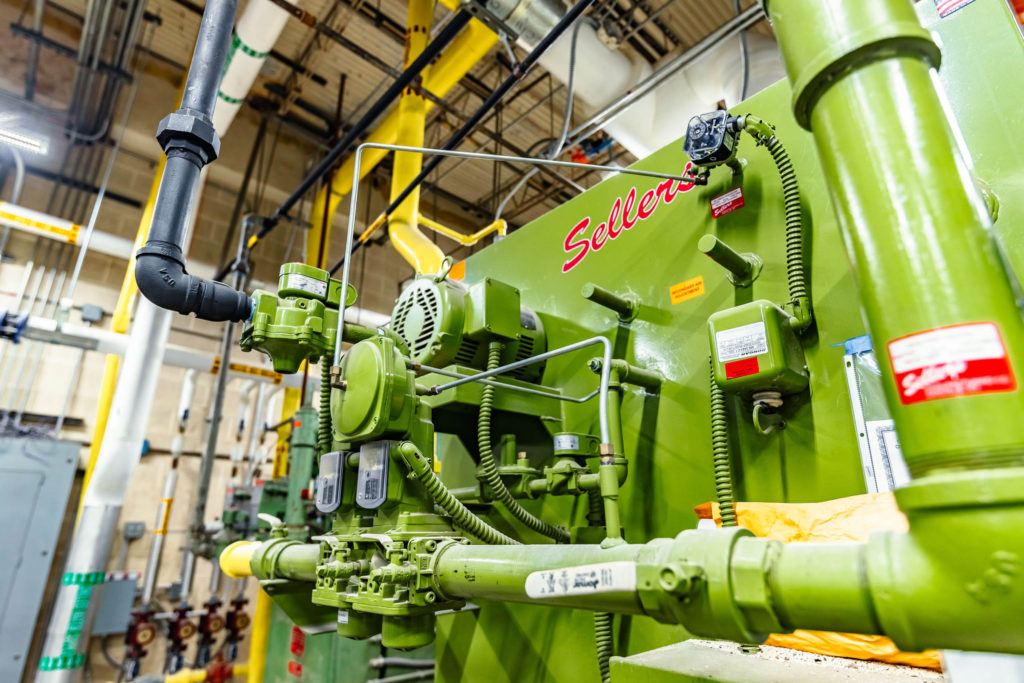

Harris MS Central Plant Replacement

KCA acted as the prime consultant on this project for San Antonio Independent School District (SAISD) and provided engineering services to facilitate a complete central plant replacement with higher efficiency equipment, which reduces overall utility usage at the campus. KCA replaced the heating hot water boilers, a total of 8,000,0000 BTUH, and the associated pumps and heating hot water piping in the central plant. KCA replaced air cooled chillers totaling 560 tons with higher efficiency equipment, replaced associated pumps and piping, and the controls for the entire central plant were reworked to provide increased energy savings throughout the campus. This project has been touted by the district as “one of the best central plants in our footprint of campuses” with regards to accessibility, maintenance access, and operation and utility savings of the installed equipment.

Colby Glass ES Addition

KCA worked closely with architectural, civil, technology, and structural consultants for Northside Independent School District (NISD) in San Antonio and provided engineering services to facilitate a complete building addition. The building addition totaled 16,000 square feet and included kindergarten classrooms, 1st grade classrooms, Advanced Learning Environment classrooms, and associated support spaces. The mechanical system installed included two single zone variable air volume air handling units, with series fan powered terminal units for increased zone control and system efficiency. KCA also replaced a 75-ton chiller that serves a small portion of the campus, as the old equipment was past its useful life.

Sam Houston HS Renovation

KCA worked closely with architectural, civil, technology, and structural consultants on a complete building addition for this project for San Antonio Independent School District (SAISD). Along with the addition, KCA also replaced the water-cooled central utility plant which serves the entire campus. The water-cooled central plant replacement increased system efficiency, and reduced utility costs throughout the campus. This project was a challenge due to existing conditions, but KCA, with all of its experience, completed the project with no change orders.

John Jay HS Boiler Replacements

KCA acted as the prime consultant for Northside Independent School District (NISD) in San Antonio and provided engineering services to facilitate a complete replacement of 2 existing boilers serving the central heating hot water system that feeds the entire campus. The systems that were replaced were old and not in proper working order. KCA provided equipment replacement to increase efficiency which reduces utility costs and improves effectiveness of the heating hot water systems.

Stuebing ES Air Cooled Chiller Replacements

KCA acted as prime consultant for Northside Independent School District (NISD) in San Antonio and provided engineering services to facilitate a complete air-cooled central plant replacement with higher efficiency equipment, which reduces overall utility usage at the campus. KCA replaced air cooled chillers totaling 340 tons with higher efficiency equipment, replaced associated pumps and piping, and the controls for the entire central plant were reworked to provide increased energy savings throughout the campus.

University Hospital

KCA acted as commissioning agent to fully retro-commission the entire central plant serving University Hospital in San Antonio. This project called on KCA to verify controls component operation, control sequence checks, controls graphics verification, chilled water and hot water system efficiency optimization, and central plant equipment evaluation of operating condition.

Bexar County Headquarters

KCA worked closely with architectural, civil, technology, and structural consultants for Bexar County, Texas and provided engineering services to facilitate a complete new building installation. The new building consists of 30,000 square feet of office space, armory spaces, technology spaces, court rooms, hearing rooms, jury rooms, and associated support spaces. This facility utilizes direct expansion variable volume rooftop units to serve the HVAC needs of the building. The electrical systems of the facility are backed by a 500kVA diesel generator, which will serve the facility for emergency power in the event of power loss at the electrical grid. Plumbing systems for the facility include water reduction measures with the implementation of a hot water recirculation system and high efficiency plumbing fixtures throughout the facility.